-

Wheel Ø75 to 200 mm

-

Rotational speedfrom 200 to 4000 rpm

-

Max cutting capacityØ 200 mm

-

Dim. W x H x D430 x 300 x 450 mm

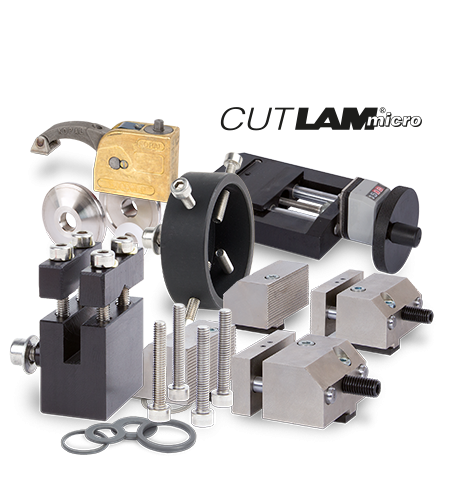

CUTLAM®micro 2.0

The sample is held in position using a vice-tightened holding arm and the wheel located outside the cutting chamber enables a micrometric movement along the Z axis; the movement can be tracked directly on the screen (accurate to 0,02 mm) Thanks to the zeroing system, very accurate parallel cuts can be performed.

A wide range of vices is available, enabling you to clamp any type of component or material. The cutting progress is either controlled manually or with a counterweight system specially adapted to delicate cuts. A rocker arm balances the implement weight, and another one permits to adjust the applied load with precision.

Design

and advanced technology

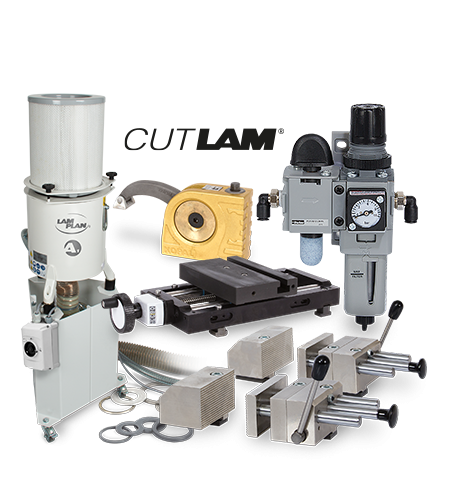

Built upon a robust, mechanically welded chassis sheathed with a painted sheet-steel body, the CUTLAM®micro 2.0 is particularly stable and is not prone to vibration, saving you valuable laboratory work space.

Technical characteristics

and equipment

Fitted with a large-capacity (10 litres, large for the machine’s size), independent filtration/decanting/recirculation tank, it is easy to perform long cuts under ideal cooling conditions. The CUTLAM®micro 2.0 has been designed to simplify maintenance and cleaning operations, the base of the cutting chamber is equipped with an inlet filter to prevent the loss of small parts and components.

A 100 µm fabric filter at the decanter inlet filters out the largest particles, and the remainder of the filtration is accomplished by decanting into a compartmented tank.

Included Equipment

-

Recirculation system, 10 litres

Recirculation system, 10 litres -

Cylindrical sample holder with clamping screw: Ø 12 to 50 mm

Cylindrical sample holder with clamping screw: Ø 12 to 50 mm -

Set of flanges: Ø 50 mm for cut-off wheel: Ø 125 to 150 mm

Set of flanges: Ø 50 mm for cut-off wheel: Ø 125 to 150 mm

Options

-

Slow speed 50 to 1000 rpm60 CTM 20 20

-

Vacuum system for holding thin sections60 CTM 03 80

Downloads

Technical data CUTLAM®micro 2.0

Wheel Ø | 75 to 200 mm |

Shaft Ø | 12,7 mm |

Standard flanges Ø | 50 mm |

Lateral arm displacement | Stroke 80 mm (accuracy 0,02 mm) |

Preload weight | 2 x 200 g |

Vertical movement | Manual |

Lubrification | Recirculation system, 10 litres, 2 compartment decantation tank, 100 µ fabric filter, recirculation pumps. 800 L/hour driven by the machine. |

Motor power | 0,6 kW |

Rotational speed | Variable, from 200 to 4000 rpm |

Protection | Transparent cover with locking system |

Touch screen 3,5“ | Intuitive and graphic interface |

Voltage | 230 V – 50 Hz single phase |

Dim. W x H x D | 430 x 300 x 450 mm (H cover open: 644 mm) |

Weight | 40 kg |

Reference | 60 CTM20 00 |

Available accessories

-

Sample holder with multi screw clamping for irregular parts

60 CTM03 50 -

Sample holder vice with clamping screw: Ø 12 mm maxi

60 CTM03 30 -

V sample holder with clamping screw: Ø 24 mm maxi

60 CTM03 20 -

Sample holder double vice with clamping screw: Ø 12 mm maxi

60 CTM03 40 -

Cylindrical sample holder with clamping screw: Ø 12 mm to 50 mm

60 CTM03 10 -

Small vice with clamping screw: Ø 12 mm

60 CTM02 10 -

Medium vice with clamping screw: Ø 24 mm

60 CTM021 10 -

Set of flanges

- Set of flanges Ø 35 mm for cut-off wheels Ø 75 to 100 mm – 60 CTM01 10

- Set of flanges Ø 75 mm cut-off wheels until Ø 200 mm – 60 CTM01 30

-

Adaptor rings (by 5) for cut-off wheels

- Steel Ø 25,4 x 12,7 mm – 60 00369 90

- PVC Ø 25,4 x 12,7 mm – 60 00370 90