-

Wheel Ø250 to 300 mm

-

Rotational speedfrom 1000 to 4000 rpm

-

Max cutting capacityØ 110 mm

-

Dim. W x H x D630 x 650 x 820 mm

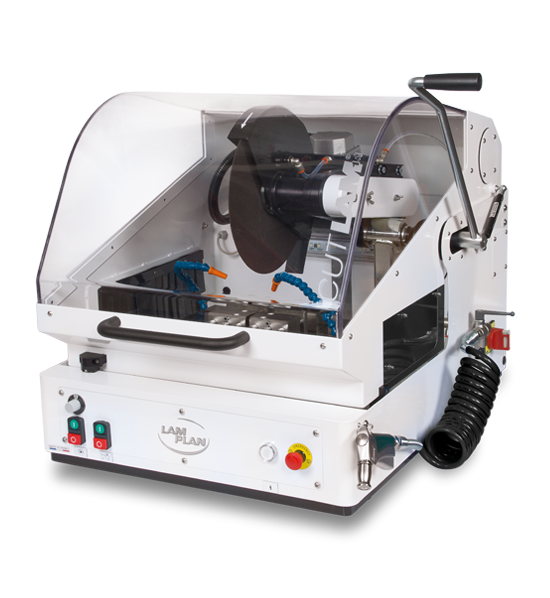

CUTLAM®1.1

This machine offers a spacious cutting table, made of treated anti corrosive cast iron. It is also easy to handle with a fully opening cover and remote motor. The 4 perpendicular grooves enable you to clamp components of thicknesses up to 120 mm. The CUTLAM®1.1 can be equipped with Ø 250 to 305 mm cut-off wheels.

Fitted with a speed adjuster and a powerful 3.8 Kw motor

particularly adapted to Ø 305 mm wheels, the CUTLAM®1.1 is perfect for intensive use.

The high-capacity recirculation system with pre-filter and decanter compartments ensures optimum lubrication and cooling by a multi-point spray.

Example of applications 1

One of the recurrent issues remaining in the cutting processes is the clamping of spherical parts. The implementation of this kind of vice on the cutlam®1.1 enables to cut spheres having a diameter going from 30 mm to 60 mm.

Example of applications 2

Tools for removing a 3 mm slice from a Ø 50 mm glass cylinder, height 50 mm. This article includes the supply and installation of a specific clamping and a double wheel on a CUTLAM® 1.1 machine.

Design

and advanced technology

The cutting chamber is illuminated by a strong and trendy aluminium projector.

The protection cover is made of two parts: a large glass area, giving a complete visibility on the cutting chamber, and a lacquered metallic belt offering a high resistance to this protection core. Furthermore, thanks to an interlocking system, this cover locks itself when the wheel is in rotation.

Technical characteristics

and equipment

An external shower head combined with a tilted cutting chamber base makes cleaning easy, and an inlet filter ensures that your samples do not fall down the large-diameter outlet pipe.

This machine is offering 2 lateral openings, giving the possibility of cutting bars which have a 60 mm diameter.

Theoretical cutting capacity: Ø 305 mm

Downloads

Technical data CUTLAM®1.1

Wheel Ø | 250 to 300 mm |

Shaft Ø | 25,4 mm |

Standard flanges Ø | 80 mm |

Max cutting capacity | Ø 110 mm (Ø 305 mm wheel) |

Passage under the wheel | 120 mm (Ø 305 mm wheel) |

Vertical movement | Manual |

Lubrification | Recirculation system, 60 litres, on casters, integrated cleaning system, with shower head located outside the cutting chamber |

Motor power | 3,8 kW |

Rotational speed | Variable, from 1000 to 4000 rpm |

Table | Groove treated stainless steel, 400 x 300 mm |

Type of groove | T groove 12 mm (2 longitudinals, 2 transversals) |

Lightening | LED |

Protection | Transparent cover with locking system |

Body | Epoxy painted coated steel |

Tension | 400 Volts – 50 Hz (three-phase) |

Dim. W x H x D | 630 x 650 x 820 mm H opened cover: 820 mm |

Poids | 125 kg |

Reference | 60 CT110 00 |

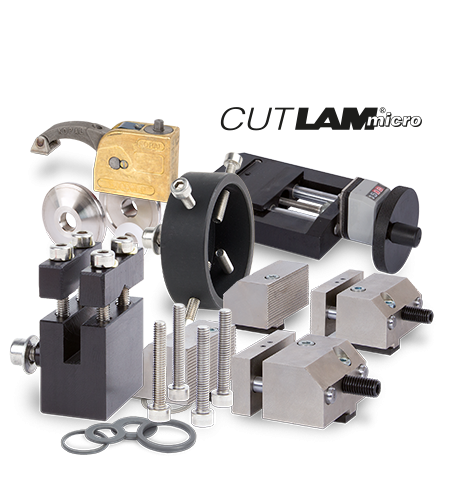

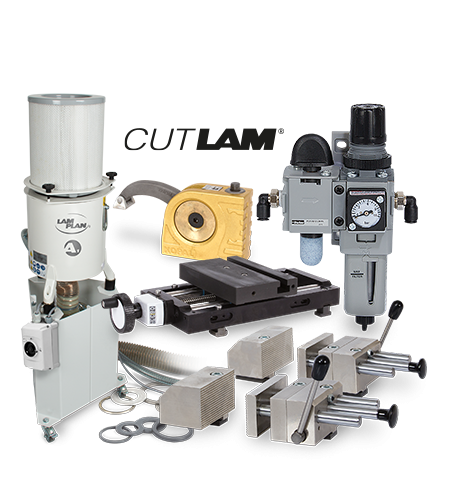

Available accessories

-

CUTLAM® support cabinet

60 M0100 00Solid painted-steel piece of furniture specially designed for CUTLAM® products.

It contains a storage door for tools and cut-off wheels, a drawer on top and a space for the recirculation tank. This piece of furniture is stable and has adjustable feet.

Dimensions: L x H x D : 630 x 800 x 835 mm.

-

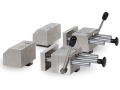

Double vice with fast tightening system (left and right side of the wheel)

60 CT200 202 x 2 elements vice, without sole, to obtain maximal length clamping

Jaw width 80 mm

Jaw height 45 mm

T-slot 12 mm screw included

Lever ( left and right ) -

Double vice with screw tightening system (left and right side of the wheel)

60 CT200 402 x 2 element vice, without sole, to obtain maximal length clamping

Jaws width 80 mm

Jaws height 45 mm

T-slot 12 mm screw included

Left and right levers -

Universal clamping KOPAL 61

60 081282 20 -

Lift for KOPAL 61

60 081282 40 -

Long cam for KOPAL 61

60 00285 90 -

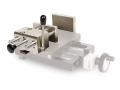

Transversal table (X movement) to perform parallel cuts.

60 CT205 20Manual movement with roller, stroke 100 mm

Display accuracy: 0,01 mm

Can receive the right vice reference 60 CT200 20 or 60 CT200 40 -

Double vice with fast tightening system

60 CT206 20For transversal table 60 CT205 20, right lever

-

Oil mist extraction device – A1

60 CT204 00The LAM PLAN vaccuming system extracts the “polluted” air inside the cutting chamber of your cutting machine.

– A special multilayer filter will stop the smallest polluting particles, thus preventing their dispersion into the atmosphere.

– The cutting fluid, in the liquid state, is returned to the cutting machine recirculation tank to be reused. (An evacuation is provided for this purpose on the vacuuming system).

– A cartridge post-filter, located above the suction system, ensures a high filtration level, up to 99.97%.

-An adapter part (LAM PLAN code 60CT20820) is provided to adapt the suction hose to the canopy of the LAM PLAN cutting machine.

– The vacuuming system is mounted on a trolley with wheels, allowing an easy positioning.

-A drain valve, located in the trolley, collects the condensate. -

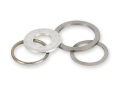

Adaptor rings (by 5) for cut-off wheels

- Steel Ø 32 x 25,4 mm – 60 00373 90

- PVC Ø 32 x 25,4 mm – 60 00374 90