-

Height300 mm

-

Width305 mm

-

Depth400 mm

-

Weight8,6 kg

INTRODUCTION

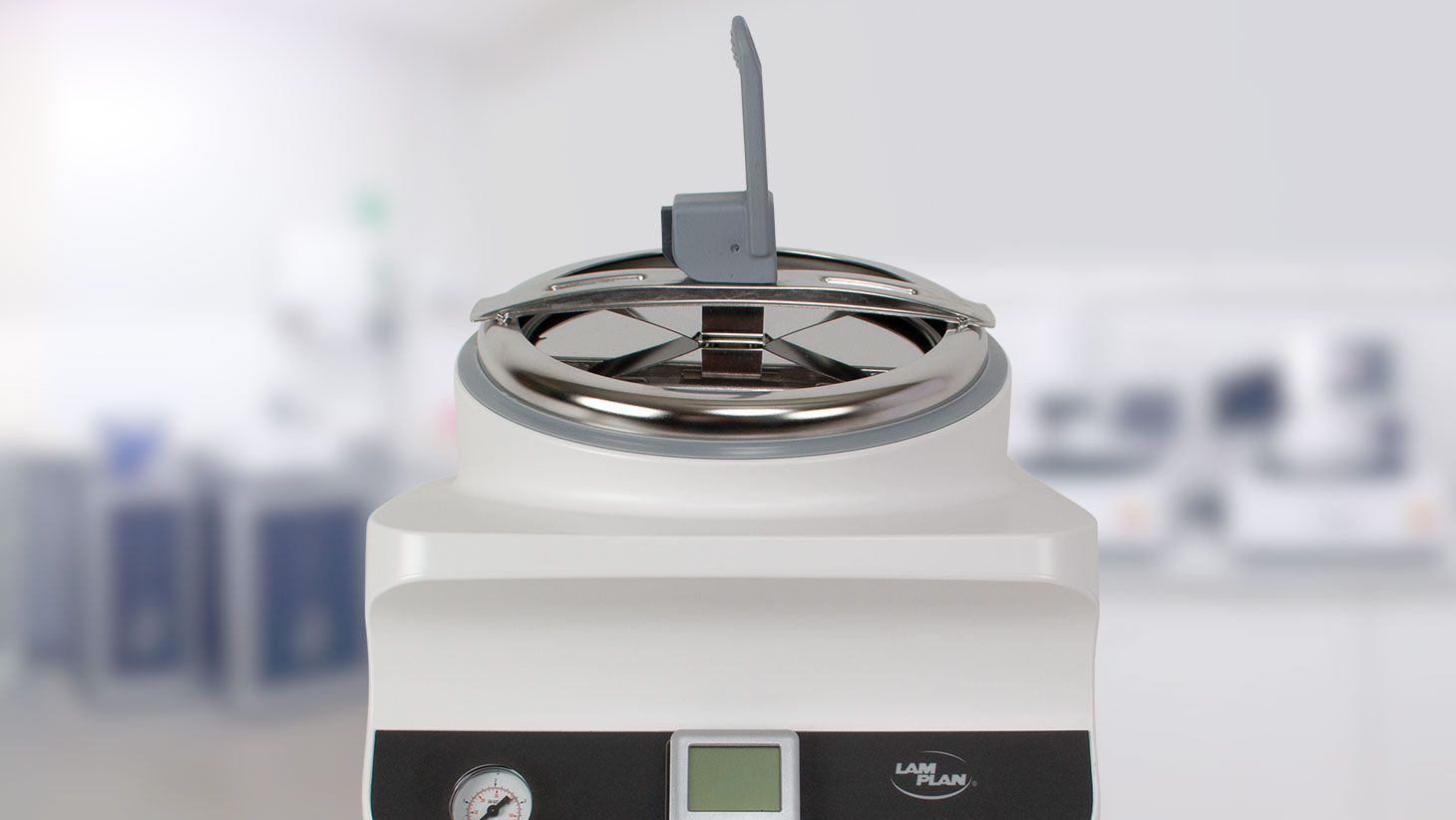

M.M.808

M.M.808 creates a pressurized environment for polymerization to avoid bubbles in the mount without affecting the physical characteristics of the resin.

While M.M.808 can be used with all cold mounting resins, it is highly recommended to be used with transparent EPOXY RESINS 603 / 603.2 and ACRYLIC RESIN 609.

VIDEO & VISUALS

Design

and advanced technology

Additionally, using the M.M.808 unit for cold mounting elimi- nates the odors typical of cold mounting resins.

Non-contractual wp-content/uploads

IN DÉTAILS

Technical characteristics

and equipment

The benefits

By avoiding entrapped bubbles in transparent mounts, the visibility of the sample can be improved.

In all cold mounting resins, avoiding bubbles improve edge retention while grinding and polishing metallographic samples.

By avoiding entrapment of abrasives in bubbles, MM808 helps improve the polishing quality after mounting.

Scope of delivery

- M.M.808 pressure polymerization device

- Quartz timer

- Operating manual

- Nozzle

Downloads

Technical data M.M.808

Pressure connection | 3 to 10 bar |

Nominal pressure | 2 bar |

Max. operating pressure | 2,8 bar |

Height | 300 mm |

Width | 305 mm |

Depth | 400 mm |

Weight | 8,6 kg |

Inner diameter of lid opening | 210 mm |

Inner diameter base | 225 mm |

Pressure pot height to cover edge | 190 mm |

Reference | 08 00808 20 |

Capacity of the pressure pot

Embedding mold Ø 25 mm | 30 pcs |

Embedding mold Ø 30 mm | 24 pcs |

Embedding mold Ø 40 mm | 15 pcs |

Embedding mold Ø 50 mm | 10 pcs |

Polymerization time

Recommended times for LAM PLAN mounting resins:

Resin 603 | 1 h polymerization – (hardening 10 h) |

Resin 603.2 | 20 min. polymerization – (hardening 2 h) |

Resin 605 | 5 – 7 min. |

Resin 607 | 16 – 20 min. |

Resin 665 | 8 – 10 min. |

Resin 609 | 9- 13 min. |

ACCESSORIES & OPTIONS

Available accessories

-

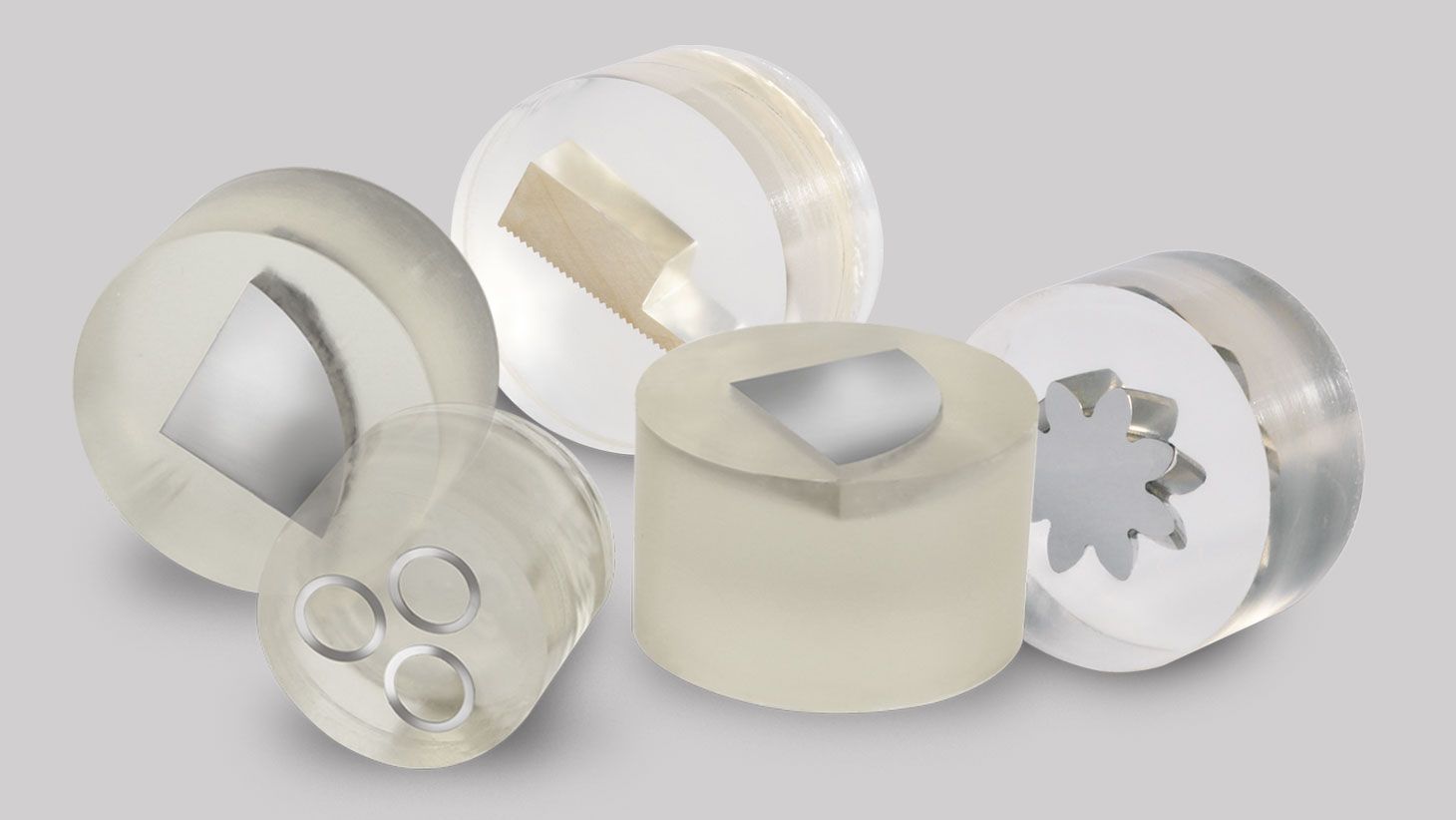

Flexible cylindrical cold mounting moulds

Available in all standard diameters for central and individual pressure sample holders, made of a flexible material to facilitate mould removal. (For an intensive use of the EPOXY 603 resin, it is preferable to use moulds with removable bottoms). -

Flexible rectangular cold mounting moulds

Specifically, for cold mounting resin, adapted to complex and nonstandard shapes, many dimensions available, made of a flexible material to facilitate mould removal, (For an intensive use of Epoxy 603, it is preferable to use removable bottom moulds). -

Moulds with removal bottom

Mainly used with the transparent mounting resins (601.2, 609, 603).

Non-contractual wp-content/uploads